Nordson® and Slautterback® are registered trademarks of the Nordson Corporation.

ITW DynatecTM is a trademark of ITW Dynatec, Inc.

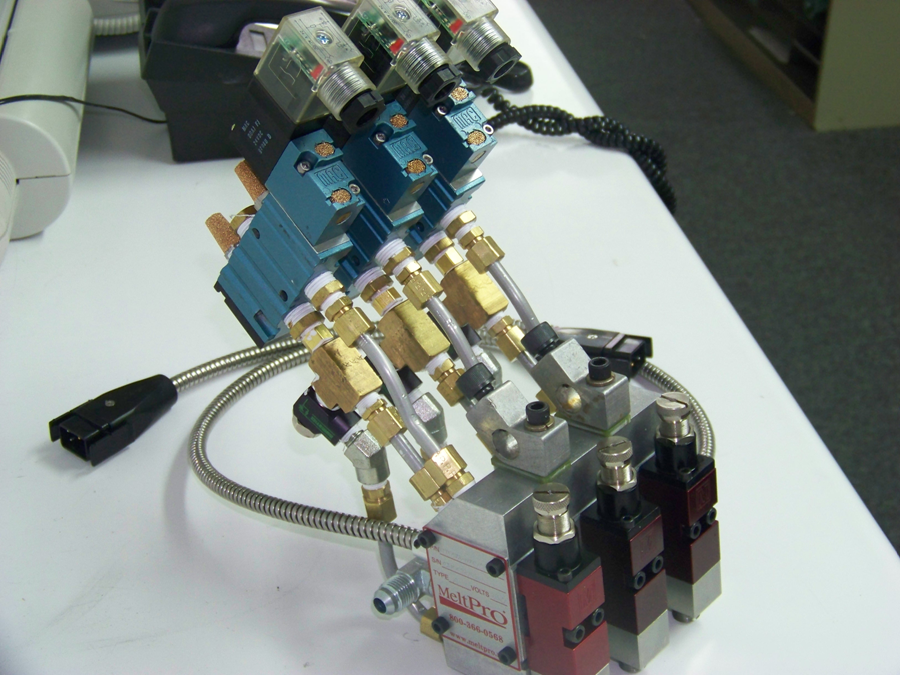

MeltPro Inc. is not affiliated with Nordson®, ITW Dynatec®, Slautterback®, or any other OEM. All OEM part numbers are for reference only.